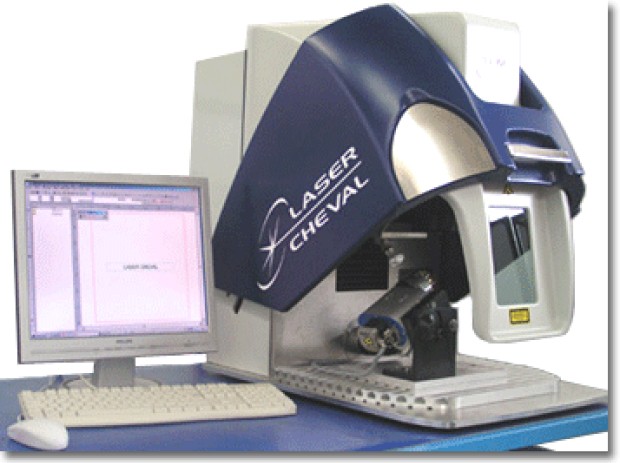

The beginnings of the Laser

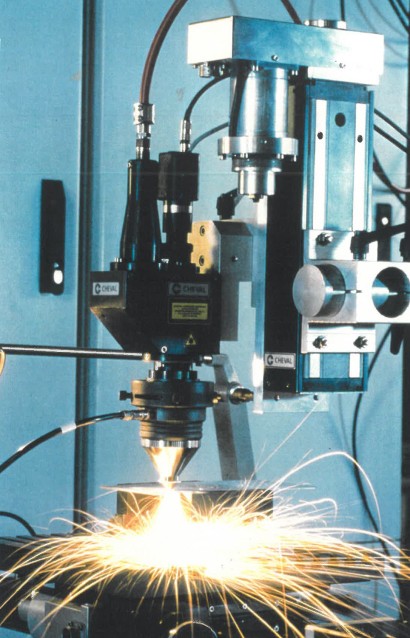

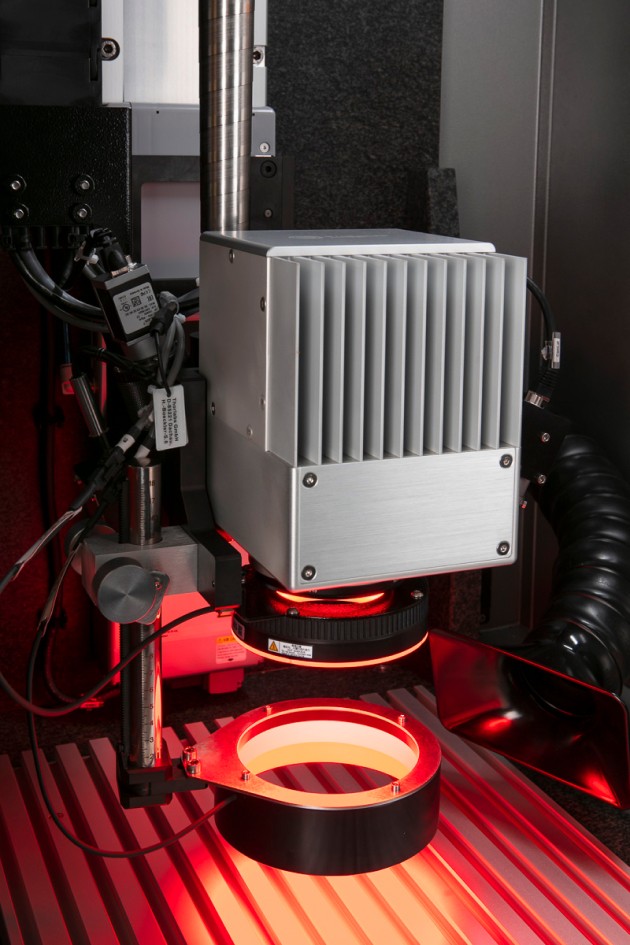

Cheval Frères, a manufacturer of watch components, needed to drill rubies. Penalised by the lack of an industrial laser on the French market, the company carried out in-depth research, which led to the importation of a source from the United States and the development of the very first ruby piercing laser. This revolutionary, computer-controlled technology, powered by a YAG laser source, marked a significant advance in the industry, reinforcing Cheval Frères' position as a pioneer of innovation in its field.